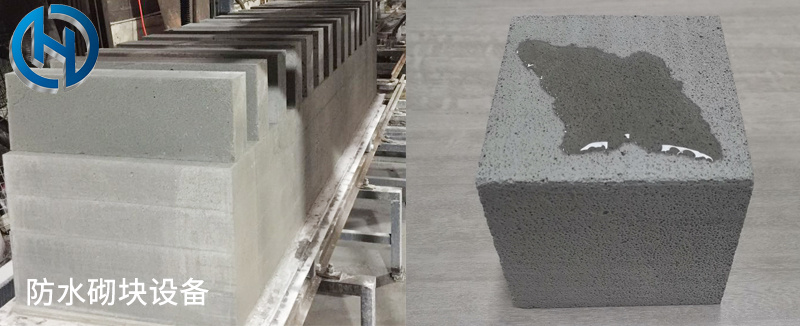

Водонепроницаемое блокировочное оборудование

Оборудование для водонепроницаемых блоков Hengde, нацеленное на решение проблемы водонепроницаемости обычных блоков (автоклавных), компания недавно внедрила запатентованную технологию и оборудование из Германии, скорректировала производственный процесс и формулу, что значительно улучшило водонепроницаемые характеристики блока, а поверхность продукта может быть непроницаемой и герметичной без специальной обработки.

Аксессуары продукта:

keyword:

keyword: Водонепроницаемое блокировочное оборудование

Product classification:

- Описание продукта

-

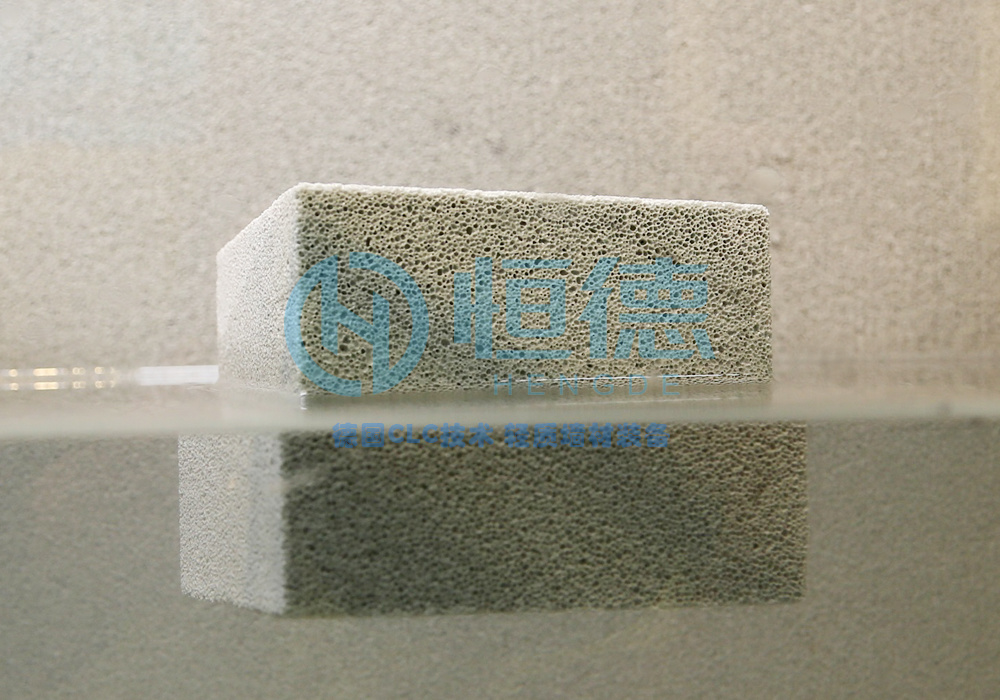

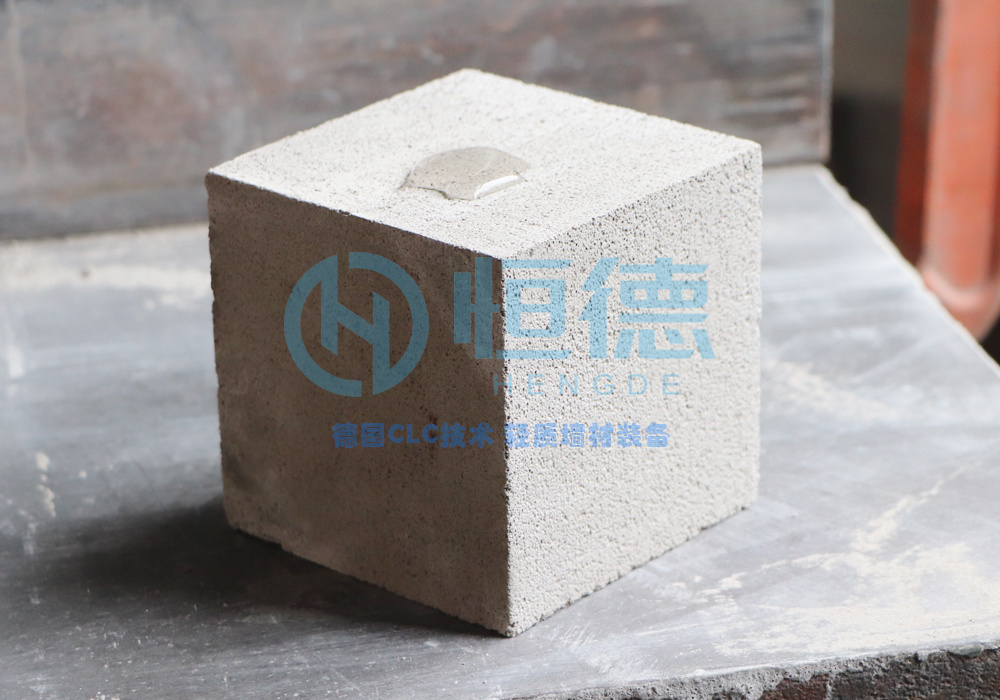

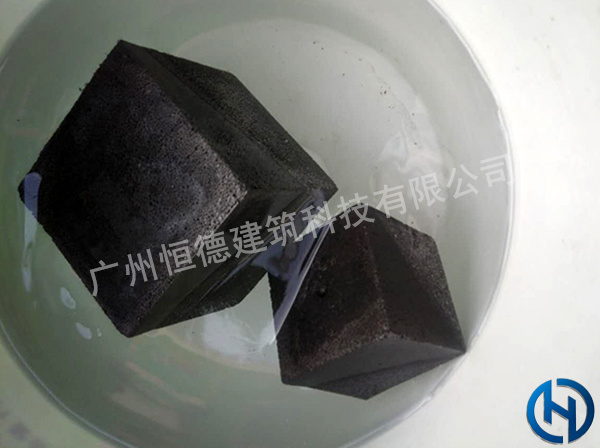

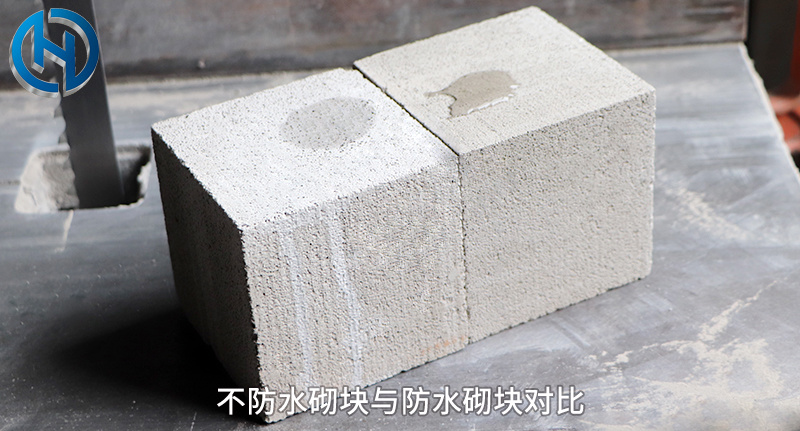

Ordinary lightweight concrete block (such as autoclaved aerated brick), due to its molding structure and production process problems, so that it can not meet the relevant requirements of the industry in terms of wall waterproof performance, it can be said that there is no waterproof effect, resulting in wall plastering hollowing, peeling, water seepage and other common building problems. Once the above quality problems are caused, the later repair cost is high and cannot be cured, especially the external wall still has potential safety hazards.After long-term research by the company, combined with the patented technology of Luka Company in Germany, on the basis of ordinary aerated concrete blocks, the waterproof requirements of the external wall are improved pertinently, and the common quality problems of autoclaved aerated concrete are completely solved.New waterproof aerated blockThe internal structure belongs to the closed independent air hole, the air hole does not communicate with each other, its structure itself has a certain waterproof function, and has good sound insulation and heat insulation performance, on this basis, combined with the special technology authorized by Lucca, Germany, to further optimize the internal structure and surface waterproof performance.

1. imported CLC block technology and waterproof process treatment technologyThe CompanyWaterproof block equipmentUsing the German Lucca authorized CLC foam concrete technology and the British CDS steam low temperature curing technology. Greatly improve the strength of lightweight concrete products, waterproof, insulation and production of environmental protection. It is more environmentally friendly and energy-saving than the traditional autoclaved aerated block production process, and the product quality is better.

1. imported CLC block technology and waterproof process treatment technologyThe CompanyWaterproof block equipmentUsing the German Lucca authorized CLC foam concrete technology and the British CDS steam low temperature curing technology. Greatly improve the strength of lightweight concrete products, waterproof, insulation and production of environmental protection. It is more environmentally friendly and energy-saving than the traditional autoclaved aerated block production process, and the product quality is better. 2. compared to other manufacturers, hengde waterproof block equipment what are the advantages?This setWaterproof block brick production equipmentUsing German imported technology and formula, a new generation of non-autoclaved environmental protection technology, mature and reliable technology, not domestic manufacturers can compare.1. Fully automatic production line:Fully automatic production line, numerical control operation, saving labor and time; Automatic metering of feeding, pouring and mixing; Low labor intensity, female workers can operate.2. Waterproof block brick technology:Using the formula and production technology imported from Germany, the block brick has good waterproof performance, which can effectively solve the problems of empty drum, peeling and water seepage of the autoclaved aerated block.3. High-precision high-speed cutting system:New research and development of high-precision block, wallboard slotting machine, size standard, no damage, no batch of ash. Suitable for long mold boxes and square mold boxes, can cut various sizes and specifications, with small waste and low cost.The newly developed high-speed cutting saw has high cutting speed, higher stability, strong durability and more convenient maintenance.(This cutting saw has a variety of models, according to demand for customers to choose)4. Air energy self-heating cycle maintenance process:The use of unique self-thermal cycle maintenance system (can be equipped with newAir energy conservation), non-autoclaved production method, no need for high temperature autoclaving, low energy consumption, environmental protection and energy saving, and good environmental assessment.5. Selection of raw materials for production:There are many choices of raw materials, which can be used locally, such as sand, fly ash, slag, stone powder, phosphogypsum, slag, industrial tailings, construction waste, etc., and the production cost is low.6. Provide a complete set of project solutions: (one machine with multiple functions)The company will help you analyze the production cost, product profit, market prospect and plant investment plan according to your local raw material price and market situation. Free newWaterproof block equipmentQuotation, project report, picture data, etc. From the initial stage of the project to the commissioning of the plant, the company will develop a comprehensive project investment plan.

2. compared to other manufacturers, hengde waterproof block equipment what are the advantages?This setWaterproof block brick production equipmentUsing German imported technology and formula, a new generation of non-autoclaved environmental protection technology, mature and reliable technology, not domestic manufacturers can compare.1. Fully automatic production line:Fully automatic production line, numerical control operation, saving labor and time; Automatic metering of feeding, pouring and mixing; Low labor intensity, female workers can operate.2. Waterproof block brick technology:Using the formula and production technology imported from Germany, the block brick has good waterproof performance, which can effectively solve the problems of empty drum, peeling and water seepage of the autoclaved aerated block.3. High-precision high-speed cutting system:New research and development of high-precision block, wallboard slotting machine, size standard, no damage, no batch of ash. Suitable for long mold boxes and square mold boxes, can cut various sizes and specifications, with small waste and low cost.The newly developed high-speed cutting saw has high cutting speed, higher stability, strong durability and more convenient maintenance.(This cutting saw has a variety of models, according to demand for customers to choose)4. Air energy self-heating cycle maintenance process:The use of unique self-thermal cycle maintenance system (can be equipped with newAir energy conservation), non-autoclaved production method, no need for high temperature autoclaving, low energy consumption, environmental protection and energy saving, and good environmental assessment.5. Selection of raw materials for production:There are many choices of raw materials, which can be used locally, such as sand, fly ash, slag, stone powder, phosphogypsum, slag, industrial tailings, construction waste, etc., and the production cost is low.6. Provide a complete set of project solutions: (one machine with multiple functions)The company will help you analyze the production cost, product profit, market prospect and plant investment plan according to your local raw material price and market situation. Free newWaterproof block equipmentQuotation, project report, picture data, etc. From the initial stage of the project to the commissioning of the plant, the company will develop a comprehensive project investment plan. 3. enterprise strength witness

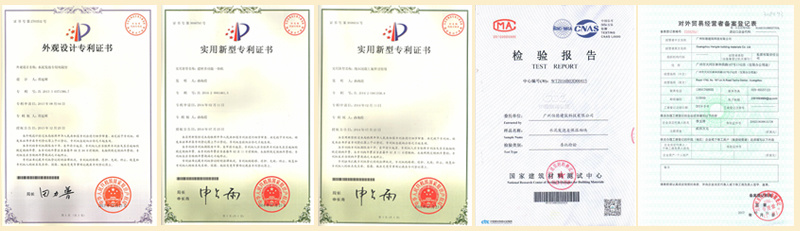

3. enterprise strength witness

A number of patents, industry standards, building energy-saving product certification

A number of patents, industry standards, building energy-saving product certification 4. project construction investment requirementsFor cooperative customers, the company will provide customers with factory planning and design free of charge. You are welcome to bring your factory drawings when you visit the factory.(I) powerhouse and water and electricity requirementsProduction plant area: 20-60 meters wide, 80-200 meters long, 6 meters highProduct maintenance area: about 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)Water consumption: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume)Raw material requirements for (II) production1. Cement: 425R Portland cement (required);2. Fly ash raw ash (optional);3. Stone powder fine powder (optional);4. Sand (silt content ≤ 2% (optional); 5. Slag powder fine powder (optional);6. Additives (provided by the company)

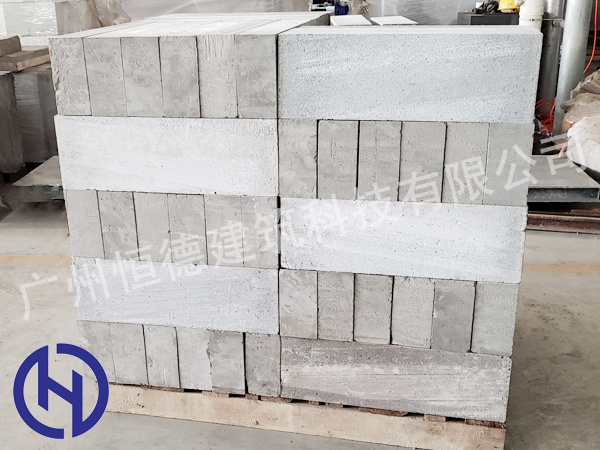

4. project construction investment requirementsFor cooperative customers, the company will provide customers with factory planning and design free of charge. You are welcome to bring your factory drawings when you visit the factory.(I) powerhouse and water and electricity requirementsProduction plant area: 20-60 meters wide, 80-200 meters long, 6 meters highProduct maintenance area: about 2000-8000 square meters (the above can be flexibly adjusted according to the output of the equipment)Water consumption: 80-500 tons/day; Electricity consumption: 200-800 kW (total power)Total factory area: 8-30 mu of land (flexibly adjusted according to sales volume)Raw material requirements for (II) production1. Cement: 425R Portland cement (required);2. Fly ash raw ash (optional);3. Stone powder fine powder (optional);4. Sand (silt content ≤ 2% (optional); 5. Slag powder fine powder (optional);6. Additives (provided by the company) 5. factory equipment delivery

5. factory equipment delivery 6. Customer Success Stories

6. Customer Success Stories 7. Product Application Cases

7. Product Application Cases the advantages of 8. waterproof block:(I) stability:Because the raw material of waterproof block is cement, fine grinding slag powder as cementing material, river sand as aggregate, concrete with air bubbles as filler, it is a hydraulic and air-hard building material. Waterproof block adopts imported formula and additives, which greatly improves the strength and stability of concrete.Light (II) capacity, reduce project cost:The general capacity of waterproof block is 800KG/M3-1300KG/M3, and the unit weight ratio is equivalent to two thirds of red brick and gray sand brick, and one half of ordinary concrete. Due to the reduction of the weight of the wall brick, the static load of the building is reduced, and the cross section of the foundation and beam column is also reduced accordingly, which greatly reduces the use of steel and concrete, thus reducing the overall project cost.(III) waterproof, impermeability strong:The raw material of waterproof block itself is water hard, gas hard material, with micro bubble structure, water absorption rate is very low, impermeability is particularly good. Exterior wall plastering only need to use cement paste brush once to do waterproof treatment after plastering, without using other waterproof materials, can achieve waterproof function, superior than other existing wall materials.(IV) good sound insulation performance:Waterproof block is forced to participate in the air during the mixing of cement and sand and other materials to form a multi-bubble structure in the concrete, and the small bubbles are evenly distributed, so the sound insulation performance is superior to other wall materials.(V) energy saving: heat insulation, fire preventionWaterproof block has good thermal insulation performance, the raw material itself is a non combustible material, more micro bubble structure, its thermal insulation and fire performance is obviously superior to other wall materials. By the national fire department inspection, 100mm thick wall fire resistance limit of more than 4 hours.

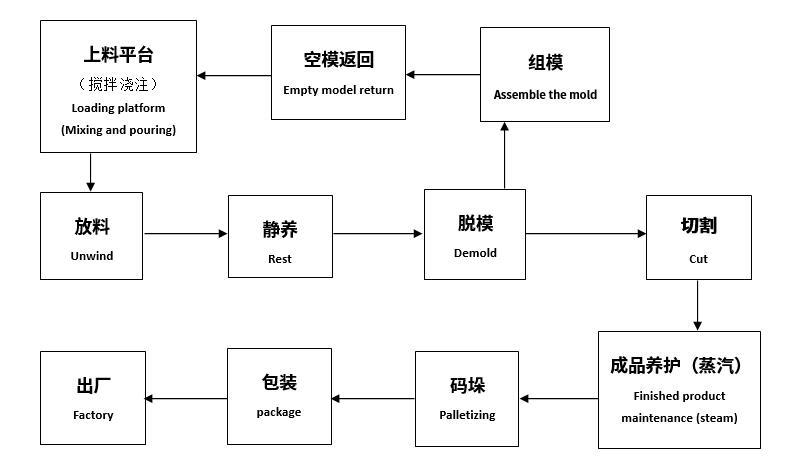

the advantages of 8. waterproof block:(I) stability:Because the raw material of waterproof block is cement, fine grinding slag powder as cementing material, river sand as aggregate, concrete with air bubbles as filler, it is a hydraulic and air-hard building material. Waterproof block adopts imported formula and additives, which greatly improves the strength and stability of concrete.Light (II) capacity, reduce project cost:The general capacity of waterproof block is 800KG/M3-1300KG/M3, and the unit weight ratio is equivalent to two thirds of red brick and gray sand brick, and one half of ordinary concrete. Due to the reduction of the weight of the wall brick, the static load of the building is reduced, and the cross section of the foundation and beam column is also reduced accordingly, which greatly reduces the use of steel and concrete, thus reducing the overall project cost.(III) waterproof, impermeability strong:The raw material of waterproof block itself is water hard, gas hard material, with micro bubble structure, water absorption rate is very low, impermeability is particularly good. Exterior wall plastering only need to use cement paste brush once to do waterproof treatment after plastering, without using other waterproof materials, can achieve waterproof function, superior than other existing wall materials.(IV) good sound insulation performance:Waterproof block is forced to participate in the air during the mixing of cement and sand and other materials to form a multi-bubble structure in the concrete, and the small bubbles are evenly distributed, so the sound insulation performance is superior to other wall materials.(V) energy saving: heat insulation, fire preventionWaterproof block has good thermal insulation performance, the raw material itself is a non combustible material, more micro bubble structure, its thermal insulation and fire performance is obviously superior to other wall materials. By the national fire department inspection, 100mm thick wall fire resistance limit of more than 4 hours. Production process flow chartAbout equipment price:Due to different output, different configurations and different prices, Guangzhou Hengde green wall material equipment can be used in one machine for multiple purposes, and a variety of products can be produced by replacing auxiliary equipment and formula. We will make configuration adjustments according to customer needs. The company's project manager will provide you with equipment quotation, project report, picture data, etc.Welcome to make an appointment in advance (hotline: 400-831-9091) to visit our Foshan factory to see the equipment and production process. We are not afraid to compare with other manufacturers.

Production process flow chartAbout equipment price:Due to different output, different configurations and different prices, Guangzhou Hengde green wall material equipment can be used in one machine for multiple purposes, and a variety of products can be produced by replacing auxiliary equipment and formula. We will make configuration adjustments according to customer needs. The company's project manager will provide you with equipment quotation, project report, picture data, etc.Welcome to make an appointment in advance (hotline: 400-831-9091) to visit our Foshan factory to see the equipment and production process. We are not afraid to compare with other manufacturers.

Сопутствующие товары

Онлайн сообщение

Мы будем Контакты вы как можно скорее